Rapid prototyping is an umbrella term for the manufacturing processes used to quickly create physical models from a digital design. By employing 2D or 3D computer-aided design (CAD) models and advanced fabrication techniques-such as 3D printing-the process provides industry professionals with a reliable and economical method of streamlining their product development processes.

At Advanced Prototype Molding (APM), we offer a broad selection of rapid prototyping services, including FDM, PolyJet, DMLS, SLS, SLA, CNC cutting, and urethane molding to help customers take their product designs from initial concept to full-scale production.

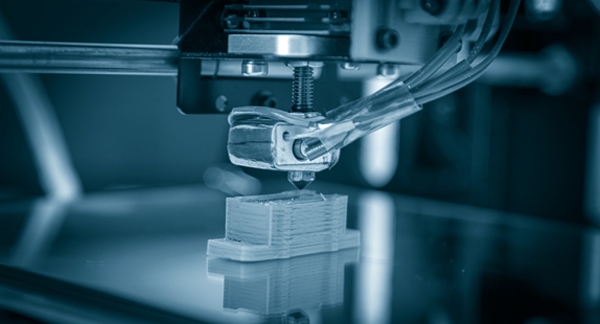

Many rapid prototyping operations employ additive manufacturing techniques-also known as 3D printing-to generate the desired physical parts, models, and/or assemblies. Compared to traditional manufacturing methods that attach separate materials together (e.g., welding) or remove excess material (e.g., machining), rapid prototyping involves the use of specialized materials-typically thermoplastics, metals, and photopolymers-that are heated, melted, and extruded to produce the pieces layer by layer.

Industry professionals often use this technique to make prototypes of new product design to test for manufacturability and functionality before proceeding to full-scale production. In addition to facilitating testing operations, prototypes allow for:

All of these qualities facilitate more streamlined product development, enabling manufacturers to design, develop, and deliver their parts and products to market faster.

Due to the numerous advantages it provides to manufacturers, rapid prototyping finds application across a diverse set of industries, including in the following:

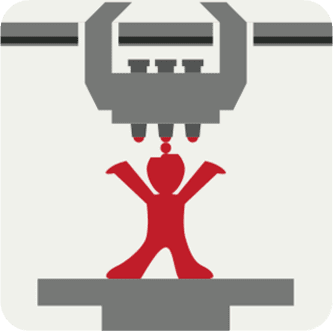

Fused deposition modeling (FDM) is one of the fastest types of rapid prototyping, making it incredibly useful in the early stages of concept design. The process binds thermoplastic layers together and can be used to create a variety of objects of varying consistencies, from hard to soft and bouncy and anywhere in between. Typical applications of prototypes produced through FDM includes design validation and testing of part properties such as strength, durability, and heat resistance. ABS and polycarb are two of the most commonly used FDM materials.

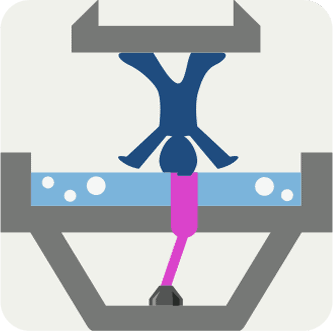

PolyJet printing accommodates the use of multiple materials of different colors, transparencies, and mechanical/physical properties, which allows for greater detail and complexity in prototypes. The process also boosts accuracies down to 0.014 millimeters. Some of the products commonly produced through PolyJet printing include high-accuracy tooling such as fixtures, jigs, and molds.

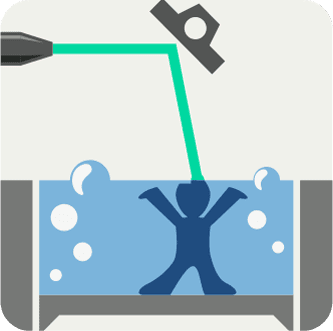

Stereolithography (SLA) is one of the most widely used rapid prototyping techniques. It uses light-sensitive liquid polymers to produce lightweight prototypes suitable for visual/conceptual demonstrations and presentations, limited functional testing, and casting pattern applications.

Stereolithography (SLA) is one of the most widely used rapid prototyping techniques. It uses light-sensitive liquid polymers to produce lightweight prototypes suitable for visual/conceptual demonstrations and presentations, limited functional testing, and casting pattern applications.

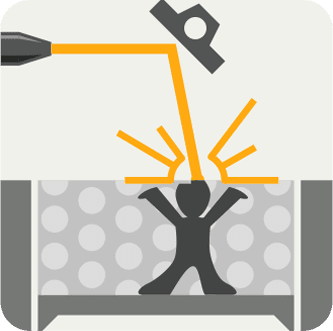

SLS creates extremely accurate and durable parts by sintering plastic powder into the desired design shape with a high-powered laser. This process is ideal for low-volume production of end-use parts, as well as rapid prototyping. SLS is relatively inexpensive compared to most other industrial additive manufacturing processes.

Advanced Prototype Molding offers Rapid Prototyping, 3D Printing and a variety of other mold making & production services all under one roof. Contact us today for more information regarding how we can be of service!

APM is an industry leader in the field of rapid prototyping. No matter what type of project you’re working on, our team of experts is ready and willing to help you determine the best way to bring your CAD model to life. To partner with us on your next project, contact us, or request a quote today.

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com